Artificial Intelligence in Manufacturing

Digitally transforming an organization is a crucial business maneuver to achieve intelligent manufacturing. Habitual execution and deployment of AI in manufacturing processes challenge leaders across technology, industry, and academicians to recognize spaces of innovation and growth. AI in Manufacturing is truly a big game-changer. It comes with the resourcefulness to remodel business horizontally and vertically throughout manufacturing operations. Yet, one can actualize its vast potential only if manufacturers refocus their energies on where AI can bring the most significant value and then push their solutions to scale.

What exactly is AI?

Artificial intelligence (AI) is a composite term for the skills exhibited by learning systems that people see as signifying intelligence. Now, standard AI aptitudes constitute speech, image, and video recognition, intelligent automation, autonomous objects, natural language processing, augmented creativity, conversational agents, advanced simulation, complex analytics, prescriptive modeling, and forecasts.

In the manufacturing operational setting, most AI use cases are clustered around the below technologies:

- Machine Learning:

The capacity of algorithms and code to utilize data and instantly learn from its inherent patterns without being expressly programmed - Deep Learning:

An exceptionally advanced type of machine learning that employs artificial neural networks to examine and evaluate images and videos - Autonomous Objects:

Artificial agents, such as collaborative robots (cobots) or autonomously guided vehicles that can control and manage a task given to them on their own

To achieve this digitally propelled success, the following steps are a great start-

- Use Flourishing AI prototypes in real Engineering Environments

The primary step in producing scale requires speeding the AI prototype with real-time data processing from the shop floor/production environment. To automate in real-time with active data collection, integrate the prototype with legacy IT systems (such as MES and ERP) and industrial Internet of Things (IIoT) systems. - Lay down a robust foundation of data Governance & AI talent.

To build a strong foundation for scale and promote fresh implementations, manufacturers must compose a data governance framework that outlines significant processes linked to production, control, and data analysis. Further, they have to extend a data & AI platform – a pivotal and central platform to collect and interpret data using AI and make it easily accessible to problem-specific AI applications. Apart from governance and platform, talent shall also be an important facet, including manufacturing-centric know-how in AI, data science, and data engineering. - Calibrate the AI Solution over the entire Manufacturing Network.

After the AI platform is prepared, AI applications can be used and made accessible across multiple worksites/factories. Performance and execution must be consistently gauged and observed for the value created output quality, and dependability.

Danone employs machine learning to forecast demand volatility and demand planning. The new ability updated its predicting process and headed to extra expert planning between diverse purposes, such as marketing and sales. It has managed to get a 20% decrease in prediction error and a 30% drop in lost sales.

Source: Gartner

Areas of Innovative AI Help in Manufacturing:

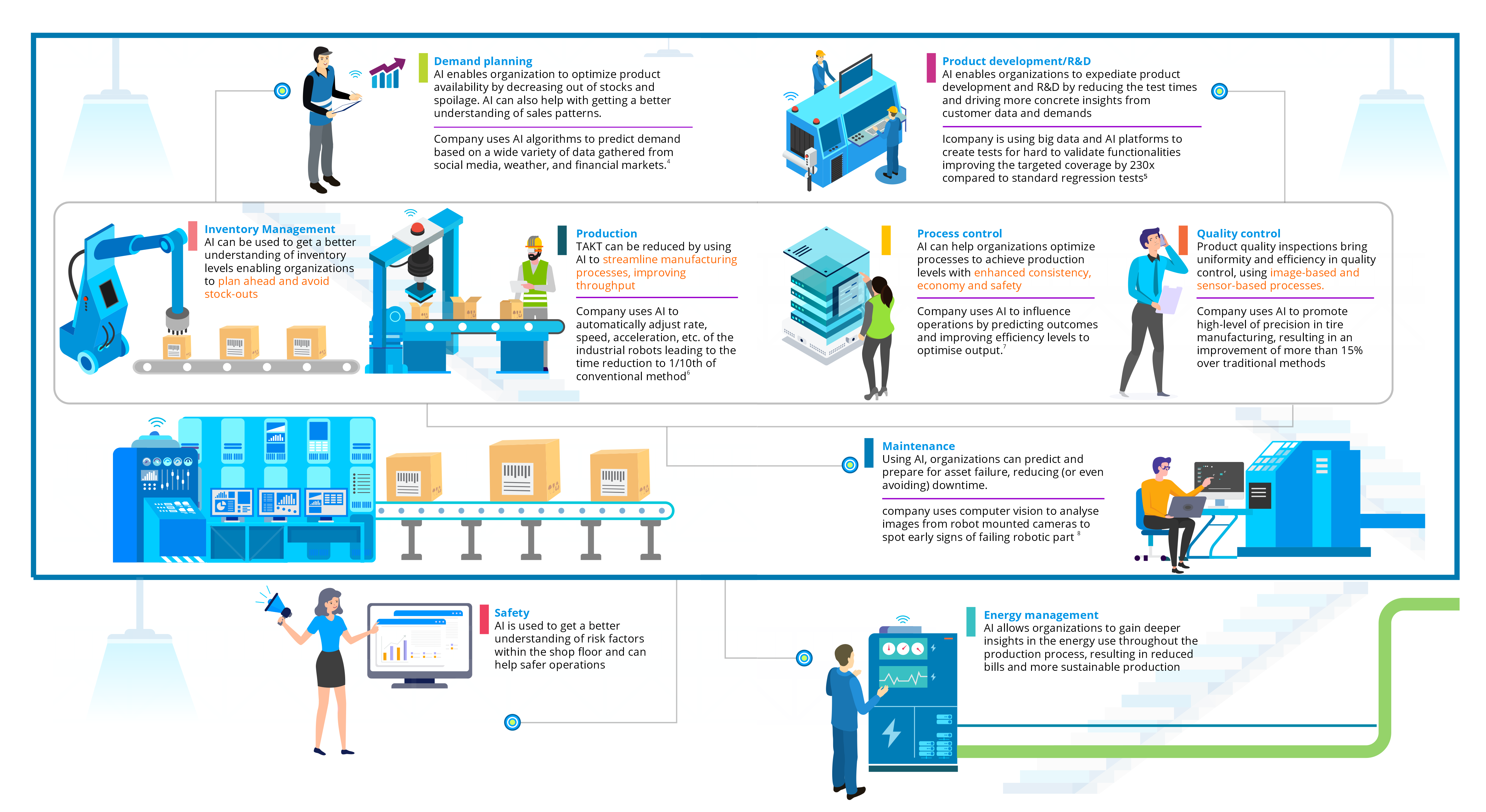

Demand Planning:

AI allows the industry to optimize product availability by reducing out-of-stock and waste or spoilage. AI can also assist with obtaining a more reliable perception of sales patterns.

Product Development or R&D:

AI empowers businesses to facilitate product development and R&D by diminishing the test times and encouraging stronger insights from client data and requirements.

Inventory Management:

AI can be utilized to acquire a stabler knowledge of inventory levels permitting companies to plan for the future and withdraw stock-outs.

Production:

TAKT (the expected product assembly time term to meet the demand) can be decreased by using AI to optimize Manufacturing processes, improving productivity and performance.

Process Control:

AI can benefit organizations in optimizing systems to gain production levels with improved consistency, saving, and security.

Quality Control:

AI also facilitates product quality reviews to thereby induce regularity and effectiveness in quality control, employing image-based and sensor-based methods.

Maintenance:

Applying AI, organizations can foretell and plan for asset breakdown, diminishing (or even preventing) downtime.

AI Use Cases in Manufacturing

Product Development/R&D:

• New product development

• Product validation in R&D

• Product enhancement

Demand Planning:

• Demand planning/forecasting

Inventory Management:

• Order optimization

• Standardized communication with suppliers using Natural Language Processing (NLP)

• Inventory planning

Process Control:

• Real-time-optimization of process parameters

• Optimize equipment changeover

Production:

• Optimizing overall productivity in the product line

• Decrease in TAKT time

• Computer vision for product identification

• Layout planning

• Collaborative robots (cobots)

Quality Control:

• Product quality inspection

• Foretelling final product quality

Maintenance:

• Intelligent maintenance

• Energy management

• Identifying irregularities in the communications network

• Worker safety and security

• Scrap/wastage minimization

• Increasing equipment efficiency

Where Do We Start?

We do not have to revamp existing processes. The solution here is to begin small. Start anywhere but start with results. Wherever it is that you plan to use AI, make sure to start with data first followed by technology. Even a tiny shift can generate exceptional results and, more importantly, let your business test the waters and then learn. If you are not certain where to start, here are a few ideas. While the offset point will differ from manufacturer to manufacturer, there are three chief entry points you could recognize:

- Quality Control

- Asset Optimization

- Operations Optimization

We have started our first AI process optimization in Quality Control on Incoming, In-process, and finished product inspection.